Home : 32mm : Tools :

Feb 2016: Added a YouTube video showing the pivoting fence in use.

Feb 2016: Added a YouTube video showing the pivoting fence in use.

Not being able to afford a sliding table saw I bought the Excalibur sliding table attachment. My review is mixed but I can say it has done wonders for productivity. I can crosscut 4x8 sheets and do all squaring, rough sizing and some final cutting of parts with it.

In the pictures, the most obvious thing I have done is to put a laminate top on the table. It came as a welded square tubing, ladder type arrangement which I did not find very practical. I also felt that delicate surfaces were at risk. I ran beads of construction adhesive on the tubing, set the laminate, a flat board and some weights on top... more

[ page | top ]

I suppose a sled is a sled, and there is nothing special about this one, but I will explain briefly. It has a 3/4" Birch plywood base with trued up 2 x 4's front and back. The runners are carefully honed steel. This is probably not a good idea because of potential wear to the saw table slots (it looks like that is just what happened). I did get some UHMW strips but never tried them so I don't know how durable this material is in this application. I do have the impression (from making some jigs) that UHMW is slick as a facing material but not when it fits snugly in a table saw slot. Using something like hard eastern maple would be easier to size and should wear pretty well. I fastened each of my steel runners in steps with three screws into the plywood. Once all was accurate I used 2 1/2" screws on each end of the runners up through the plywood and into the 2x 4's. I could have probably simplified this by carefully cutting dados, maybe 3/16" deep, for the runners.

I suppose a sled is a sled, and there is nothing special about this one, but I will explain briefly. It has a 3/4" Birch plywood base with trued up 2 x 4's front and back. The runners are carefully honed steel. This is probably not a good idea because of potential wear to the saw table slots (it looks like that is just what happened). I did get some UHMW strips but never tried them so I don't know how durable this material is in this application. I do have the impression (from making some jigs) that UHMW is slick as a facing material but not when it fits snugly in a table saw slot. Using something like hard eastern maple would be easier to size and should wear pretty well. I fastened each of my steel runners in steps with three screws into the plywood. Once all was accurate I used 2 1/2" screws on each end of the runners up through the plywood and into the 2x 4's. I could have probably simplified this by carefully cutting dados, maybe 3/16" deep, for the runners.

The sled has a capacity of approximately 27" which is, more often than not, an adequate and practical size. For long stuff I have a 3/4 strip with stops that fits on the end of the table extension (visible on the right edge of the photo). You can also see the slots in the rear extension table for the runners as they pass the back side of the saw. These are oversize to leave room for sawdust and to avoid any contact with the runners.

[ comment | link | top ]

The 5-cut method is a very accurate way to check a sliding table, sled or miter fence for squareness to the sawblade. I ran across this while watching a Laguna Tools video. Hopefully the drawing is self descriptive. Different setups will call for either a clockwise or counterclockwise rotation. The example image is for a front fence to the left of the blade (counterclockwise). With the same setup and the fence to the rear, the rotation would be counterclockwise. In any case, if the wider end of the cutoff piece is closer to the blade, the fence is greater than 90 degrees to the blade (smaller is less than 90). The bigger the piece of material you use, the more accurate you can be.

The 5-cut method is a very accurate way to check a sliding table, sled or miter fence for squareness to the sawblade. I ran across this while watching a Laguna Tools video. Hopefully the drawing is self descriptive. Different setups will call for either a clockwise or counterclockwise rotation. The example image is for a front fence to the left of the blade (counterclockwise). With the same setup and the fence to the rear, the rotation would be counterclockwise. In any case, if the wider end of the cutoff piece is closer to the blade, the fence is greater than 90 degrees to the blade (smaller is less than 90). The bigger the piece of material you use, the more accurate you can be.

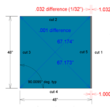

I made the image at right with Drafix CAD. I figure that a 32nd of an inch is as accurate as you can get with a tape measure. As you can see a 1/32" difference with the five cut method equals a mere .001" difference on the diagonal. Diagonal measuring doesn't work if you really want to be square. If you *really* want to get precise you can use a caliper with this method. You do need to consider the limits of your tooling, how much slop is in the runners or bearings etc., before trying to get within .001 (probably totally unrealistic) with this method... This is a bit overstated in that you typically have two parallel edges and your crosscuts will have two angles greater than 90 and 2 angles less than 90, not the four greater than 90 in the drawing, i.e. there would be a bigger difference on the diagonal.

I made the image at right with Drafix CAD. I figure that a 32nd of an inch is as accurate as you can get with a tape measure. As you can see a 1/32" difference with the five cut method equals a mere .001" difference on the diagonal. Diagonal measuring doesn't work if you really want to be square. If you *really* want to get precise you can use a caliper with this method. You do need to consider the limits of your tooling, how much slop is in the runners or bearings etc., before trying to get within .001 (probably totally unrealistic) with this method... This is a bit overstated in that you typically have two parallel edges and your crosscuts will have two angles greater than 90 and 2 angles less than 90, not the four greater than 90 in the drawing, i.e. there would be a bigger difference on the diagonal.

[ comment | link | top ]

Cutting

This category currently consists of topics posted to the old 32mm site. They were written quite a few years ago. I still use the Excalibur sliding table to cut all my panels.

Excalibur Sliding Table

Feb 2016: Added a YouTube video showing the pivoting fence in use.

Feb 2016: Added a YouTube video showing the pivoting fence in use.Not being able to afford a sliding table saw I bought the Excalibur sliding table attachment. My review is mixed but I can say it has done wonders for productivity. I can crosscut 4x8 sheets and do all squaring, rough sizing and some final cutting of parts with it.

In the pictures, the most obvious thing I have done is to put a laminate top on the table. It came as a welded square tubing, ladder type arrangement which I did not find very practical. I also felt that delicate surfaces were at risk. I ran beads of construction adhesive on the tubing, set the laminate, a flat board and some weights on top... more

[ page | top ]

Crosscut Sled

I suppose a sled is a sled, and there is nothing special about this one, but I will explain briefly. It has a 3/4" Birch plywood base with trued up 2 x 4's front and back. The runners are carefully honed steel. This is probably not a good idea because of potential wear to the saw table slots (it looks like that is just what happened). I did get some UHMW strips but never tried them so I don't know how durable this material is in this application. I do have the impression (from making some jigs) that UHMW is slick as a facing material but not when it fits snugly in a table saw slot. Using something like hard eastern maple would be easier to size and should wear pretty well. I fastened each of my steel runners in steps with three screws into the plywood. Once all was accurate I used 2 1/2" screws on each end of the runners up through the plywood and into the 2x 4's. I could have probably simplified this by carefully cutting dados, maybe 3/16" deep, for the runners.

I suppose a sled is a sled, and there is nothing special about this one, but I will explain briefly. It has a 3/4" Birch plywood base with trued up 2 x 4's front and back. The runners are carefully honed steel. This is probably not a good idea because of potential wear to the saw table slots (it looks like that is just what happened). I did get some UHMW strips but never tried them so I don't know how durable this material is in this application. I do have the impression (from making some jigs) that UHMW is slick as a facing material but not when it fits snugly in a table saw slot. Using something like hard eastern maple would be easier to size and should wear pretty well. I fastened each of my steel runners in steps with three screws into the plywood. Once all was accurate I used 2 1/2" screws on each end of the runners up through the plywood and into the 2x 4's. I could have probably simplified this by carefully cutting dados, maybe 3/16" deep, for the runners.The sled has a capacity of approximately 27" which is, more often than not, an adequate and practical size. For long stuff I have a 3/4 strip with stops that fits on the end of the table extension (visible on the right edge of the photo). You can also see the slots in the rear extension table for the runners as they pass the back side of the saw. These are oversize to leave room for sawdust and to avoid any contact with the runners.

[ comment | link | top ]

Square Cutting Panels

The 5-cut method is a very accurate way to check a sliding table, sled or miter fence for squareness to the sawblade. I ran across this while watching a Laguna Tools video. Hopefully the drawing is self descriptive. Different setups will call for either a clockwise or counterclockwise rotation. The example image is for a front fence to the left of the blade (counterclockwise). With the same setup and the fence to the rear, the rotation would be counterclockwise. In any case, if the wider end of the cutoff piece is closer to the blade, the fence is greater than 90 degrees to the blade (smaller is less than 90). The bigger the piece of material you use, the more accurate you can be.

The 5-cut method is a very accurate way to check a sliding table, sled or miter fence for squareness to the sawblade. I ran across this while watching a Laguna Tools video. Hopefully the drawing is self descriptive. Different setups will call for either a clockwise or counterclockwise rotation. The example image is for a front fence to the left of the blade (counterclockwise). With the same setup and the fence to the rear, the rotation would be counterclockwise. In any case, if the wider end of the cutoff piece is closer to the blade, the fence is greater than 90 degrees to the blade (smaller is less than 90). The bigger the piece of material you use, the more accurate you can be. I made the image at right with Drafix CAD. I figure that a 32nd of an inch is as accurate as you can get with a tape measure. As you can see a 1/32" difference with the five cut method equals a mere .001" difference on the diagonal. Diagonal measuring doesn't work if you really want to be square. If you *really* want to get precise you can use a caliper with this method. You do need to consider the limits of your tooling, how much slop is in the runners or bearings etc., before trying to get within .001 (probably totally unrealistic) with this method... This is a bit overstated in that you typically have two parallel edges and your crosscuts will have two angles greater than 90 and 2 angles less than 90, not the four greater than 90 in the drawing, i.e. there would be a bigger difference on the diagonal.

I made the image at right with Drafix CAD. I figure that a 32nd of an inch is as accurate as you can get with a tape measure. As you can see a 1/32" difference with the five cut method equals a mere .001" difference on the diagonal. Diagonal measuring doesn't work if you really want to be square. If you *really* want to get precise you can use a caliper with this method. You do need to consider the limits of your tooling, how much slop is in the runners or bearings etc., before trying to get within .001 (probably totally unrealistic) with this method... This is a bit overstated in that you typically have two parallel edges and your crosscuts will have two angles greater than 90 and 2 angles less than 90, not the four greater than 90 in the drawing, i.e. there would be a bigger difference on the diagonal.

[ comment | link | top ]

Melamine

To get a good cut on both sides is dependent on your material and blade. I make a living doing this so I want to make my cuts once. There are other methods you can try that require 2 passes or pre scoring. Notes: There are other similar materials to melamine that I have no experience with. When buying melamine make sure you are getting a pine core as it is a lot more forgiving than a fir core... more

[ page | comments (1) - Friday, 19-Dec-2008 | top ]

[ page | comments (1) - Friday, 19-Dec-2008 | top ]

Methods

There are a number of things you can try for cutting melamine and/or veneer. I have not used any extensively preferring a good blade and a single pass on the saw. These methods are worth trying if you do not have a high quality 80 tooth carbide blade or if you do and it is dull or otherwise not giving you the results you want... more

[ page | top ]

[ page | top ]